Attic insulation refers to the material used to reduce the transfer of heat between the living space and the attic. It serves as a barrier to maintaining a comfortable temperature inside the home by preventing the loss of heat during colder months and keeping heat out during warmer seasons.

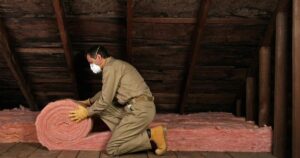

The insulation is typically installed in the attic space, either between the ceiling joists or rafters, helping to regulate the indoor climate and improve energy efficiency. Common materials for insulation include fiberglass, cellulose, spray foam, or mineral wool, each with its unique properties and installation methods.

Attic insulation is a fundamental component of a home’s energy efficiency and comfort. It plays a crucial role in reducing energy costs by minimizing heat loss and gain. By creating a thermal barrier, insulation helps maintain a consistent indoor temperature, reducing the strain on heating and cooling systems.

Importance of Attic Insulation

Size of the Attic

The size of the attic directly influences the time required for insulation. Smaller spaces (under 500 sq. ft.) generally take less time to insulate compared to larger ones (over 1000 sq. ft.).

Type of Insulation Material

Different materials vary in their installation methods and complexities. For instance, spray foam might require more time due to its application process compared to laying down rolls of fiberglass insulation.

Accessibility and Obstacles

Attics with easy access and minimal obstructions are quicker to insulate. However, attics with complex layouts, multiple obstacles, or limited access points might require more time.

Experience and Expertise of the Installer

The proficiency of the installer significantly affects the duration of the insulation process. Experienced professionals are generally more efficient and can complete the task more quickly compared to those with limited experience.

Size of the Attic

Estimating the time required for attic insulation depends significantly on the attic’s size. Smaller attics, typically under 500 square feet, generally require less time for insulation. The installation process for smaller spaces is more straightforward and can be completed relatively quickly compared to larger attics.

Conversely, larger attics, those exceeding 1000 square feet, demand more time due to the increased area that needs insulation. This means more material to install, more surface area to cover, and often more intricate layouts, consequently extending the insulation timeline.

Type of Insulation Material

The type of insulation material chosen for the attic directly impacts the time required for installation. For instance, loose-fill insulation materials such as cellulose may take longer to install than pre-cut batts or rolls of fiberglass insulation.

Spray foam insulation, while highly effective, often demands more time due to its application process, which involves mixing, spraying, and curing.

Each material has its unique installation methods, affecting the duration of the insulation process. Some materials might require specialized equipment or techniques, further influencing the time needed for completion.

Accessibility and Obstacles

The ease of access and the presence of obstacles in the attic significantly affect the duration of insulation. Attics with straightforward access and minimal obstructions, such as air ducts, wiring, or structural barriers, generally allow for a more streamlined insulation process.

Attics with complex layouts, multiple obstructions, or limited entry points may pose challenges and thus require more time for installation.

Installers may need to navigate around obstacles, create access points, or work more meticulously in confined or challenging spaces, extending the overall time needed to insulate the attic.

Experience and Expertise of the Installer

The experience and expertise of the individual or team performing the insulation play a crucial role in determining the duration of the process. Experienced professionals with a deep understanding of insulation methods and best practices are typically more efficient and can work faster compared to those with limited experience.

Seasoned installers are adept at navigating various attic layouts, handling different insulation materials, and efficiently addressing potential challenges that might arise during the installation. Conversely, less experienced installers might require more time to complete the task, as they may need to reference guidelines or encounter difficulties that could prolong the insulation process.

Estimating Time Required

Small Attics (under 500 sq. ft.)

Typically, smaller attics take less time to insulate, usually ranging from a few hours to a day, depending on the complexity of the layout and insulation material.

Medium Attics (500-1000 sq. ft.)

Insulating attics within this size range may take a day or two, considering the additional surface area and potential obstacles that could affect the installation process.

Large Attics (over 1000 sq. ft.)

Attics exceeding 1000 square feet can take several days to a week or more, depending on the intricacy of the layout, the chosen insulation material, and the level of expertise of the installers.

Different Insulation Types and Their Impact on Time

The choice of insulation material significantly impacts the time required for installation. Spray foam or blown-in insulation, for example, might take longer due to their application techniques compared to more straightforward batt or roll insulation methods.

The specific characteristics and intricacies of each insulation type contribute to variations in the time needed for installation.

Process of Attic Insulation

Preparing the attic space involves clearing the area of debris, ensuring proper ventilation, and addressing any repairs or improvements required before the insulation process begins. This step may involve tasks such as sealing air leaks, fixing roof issues, and creating a clean and suitable environment for the insulation material to be installed.

The time taken for preparation varies based on the condition of the attic and the extent of necessary pre-insulation work.

Installing Insulation Material

The installation of insulation material includes laying, spraying, or blowing in the chosen insulation type into the designated areas of the attic. The time required for this stage varies depending on the type of material, the surface area to be covered, and any intricacies in the attic’s layout.

Installation may require cutting and fitting insulation pieces to cover specific spaces accurately or evenly distributing loose-fill insulation, affecting the overall time taken.

Sealing Air Leaks

Sealing air leaks is a crucial step in the insulation process to ensure the effectiveness of the insulation. This involves identifying and sealing gaps, cracks, or holes that might allow air to escape or enter the attic space. The time required for this task varies based on the number and size of leaks present, requiring thorough inspection and precise sealing.

Clean-up and Final Inspection

After the insulation is installed, a thorough clean-up of the workspace is necessary. This involves removing any leftover materials, and tools, and ensuring the attic is left in a tidy state. A final inspection to ensure the quality of installation and to verify that all areas are adequately insulated is also conducted at this stage, adding to the overall time required for the insulation process.

Clean-up and Final Inspection

The clean-up and final inspection stage in attic insulation are critical for ensuring the quality and success of the installation process. Once the insulation material is in place, a thorough clean-up is conducted to remove any debris, leftover insulation, or tools used during the process. This step helps in leaving the attic space organized and ready for use.

Following the clean-up, a meticulous final inspection is carried out to check for any missed spots or areas that might need rework. Inspectors ensure that the insulation is evenly distributed, all areas are adequately covered, and any potential issues are identified and rectified. This final check guarantees the efficiency and effectiveness of the insulation, ensuring the desired outcome of energy efficiency and climate control within the home.

Tips for Efficient Attic Insulation

Here are a few tips for efficient Attic Insulation.

Proper Planning and Preparation

Adequate planning and preparation before beginning the insulation process are crucial for efficiency. This includes assessing the attic space, identifying any required repairs, and making necessary adjustments before the installation. Proper planning helps streamline the process and prevents interruptions or delays during installation.

Utilizing Appropriate Tools and Equipment

Using the right tools and equipment tailored to the chosen insulation material enhances efficiency. The correct tools ensure precise installation, reducing the time required and ensuring the quality of work.

Safety Measures

Prioritizing safety measures during installation not only protects the installers but also contributes to a more efficient process. Implementing safety protocols reduces the risk of accidents or delays, allowing the task to proceed smoothly and without interruption.

Proper Planning and Preparation

Effective attic insulation begins with meticulous planning and preparation. Assessing the attic’s condition, identifying any leaks, and repairing structural issues before the insulation process ensures a smooth installation.

Adequate planning also involves calculating the required amount of insulation material and making arrangements for its delivery, reducing interruptions during the installation.

Utilizing Appropriate Tools and Equipment

Selecting and utilizing the right tools and equipment specific to the insulation material being used is essential for a successful insulation process. Whether it’s cutting tools for fiberglass, spraying equipment for foam insulation, or protective gear for safety, having the appropriate tools ensures precise installation and a more efficient workflow.

Safety Measures

Implementing safety measures throughout the insulation process is paramount. This includes using protective gear, ensuring proper ventilation in the attic, and following safety guidelines for the specific insulation material.

Prioritizing safety not only safeguards the installers but also contributes to a more efficient and uninterrupted installation process.

FAQ’s

How long does insulation work take?

Most jobs will take one to two days from start to finish. Both closed-cell and open-cell spray foam insulation will dry and cure fast enough that your family can enjoy the benefits of insulation within hours.

How fast does insulation dry?

If the source of moisture is from the inside of a wall (for example a pipe leak in the wall), and if the insulation is not dry within 2-3 days.

Conclusion

Attic insulation is a crucial aspect of maintaining a comfortable, energy-efficient home. Adequate insulation helps in controlling indoor temperatures, reducing energy costs, and ensuring the longevity of the building structure. Proper planning, choice of materials, and adherence to safety measures are vital for an effective and efficient insulation process.

Adequate attic insulation plays a vital role in maintaining energy efficiency and the overall comfort of a home. It reduces heat transfer, minimizes energy costs, and contributes to the structural durability of the building by preventing moisture-related issues and temperature fluctuations. The significance of insulation in creating a comfortable living environment cannot be overstated.