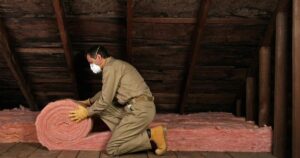

Blown-in insulation is a versatile method used to insulate homes and buildings. Its primary purpose is to reduce heat transfer, maintain indoor temperatures, and enhance energy efficiency. This technique involves blowing or spraying insulation material into cavities, filling them effectively.

Determining the appropriate thickness of blown-in insulation is crucial for effective energy efficiency in a building. The right thickness ensures proper insulation and helps maintain a comfortable indoor environment.

Insulation refers to loose, often recycled material blown or sprayed into spaces using special equipment. It’s commonly used in attics and walls to improve a building’s thermal performance. The thickness required depends on various factors such as the climate, desired R-value, and the type of insulation material used.

Definition and Purpose

Blown-in insulation involves loose fibers or particles, which are blown into areas to fill and insulate spaces, providing thermal resistance. Its purpose is to reduce heat flow, keeping indoor temperatures stable and energy costs lower. This insulation method effectively seals gaps and cavities, reducing heat transfer and maintaining comfort within buildings.

Types of Blown-In Insulation

Several types of blown-in insulation exist, with some common varieties being fiberglass, cellulose, and mineral wool. Fiberglass consists of fine glass fibers, cellulose comprises recycled paper or cardboard, while mineral wool is made from rock or slag. Each type has its distinct characteristics and insulation properties.

Factors Affecting Thickness

The thickness of insulation is influenced by various factors. Climate considerations play a significant role, as different regions require different R-values and insulation thicknesses. Desired R-values, the type of insulation material used, and whether it’s for attic or wall insulation also affect the required thickness.

Determining Thickness for Blown-In Insulation

Determining the appropriate thickness for blown-in insulation involves multiple considerations. Climate plays a crucial role, as areas with extreme temperatures may require thicker insulation. The desired R-value, type of insulation material, and whether it’s for the attic or wall insulation are also crucial factors.

Climate Considerations

The climate of a region dictates the required thickness of blown-in insulation. Colder regions typically require thicker insulation for higher R-values to prevent heat loss, while warmer areas might need less insulation for lower R-values to prevent heat gain.

Desired R-Value

The desired R-value determines the level of thermal resistance needed in insulation. Higher R-values require thicker insulation to provide better insulation performance, maintaining comfortable indoor temperatures.

Type of Insulation Material

Different types of blown-in insulation materials have varying insulation properties. Fiberglass, cellulose, and mineral wool each have different capabilities, affecting the required thickness for achieving optimal insulation.

Attic or Wall Insulation

The location of insulation—whether in the attic or walls—affects the required thickness. Attics often need thicker insulation to prevent heat loss through the roof, while wall insulation requirements might vary based on the construction and regional climate.

Recommended Thickness Guidelines

Recommended guidelines for blown-in insulation thickness are based on several factors, including general R-value requirements, common insulation material thicknesses, manufacturer recommendations, and installation considerations.

General R-Value Requirements

General R-value requirements vary by region and climate. They determine the level of insulation needed, guiding the thickness of blown-in insulation for optimal thermal resistance.

Common Insulation Material Thickness

Different insulation materials have typical thickness recommendations based on their R-value and composition. Understanding these thickness guidelines helps in achieving effective insulation.

Manufacturer Recommendations

Manufacturers provide specific guidelines for their insulation products. These recommendations often consider the material’s thermal properties and are crucial in determining the appropriate thickness for effective insulation.

Installation Considerations

The method and quality of installation significantly impact the required thickness of blown-in insulation. Proper installation techniques ensure even coverage and effective insulation performance.

Benefits of Adequate Insulation Thickness

Ensuring the appropriate thickness of blown-in insulation offers several advantages. These include enhanced energy efficiency, improved thermal comfort, and cost savings.

Energy Efficiency

Adequate insulation thickness reduces heat transfer, leading to increased energy efficiency by maintaining stable indoor temperatures without overreliance on heating or cooling systems.

Thermal Comfort

Proper insulation thickness helps maintain consistent indoor temperatures, ensuring thermal comfort year-round, regardless of external weather conditions.

Cost Savings

Effective insulation thickness reduces energy consumption, leading to cost savings on heating and cooling bills. Maintaining optimal insulation levels minimizes the need for excessive heating or cooling, resulting in reduced utility expenses.

FAQ’s

How thick is R-38 blown insulation?

Cellulose attains an R-38 rating with approximately 10-inches of thickness, whereas fiberglass needs to be about 12-inches thick to achieve the same performance, this makes cellulose far more effective per inch.

Why is thicker insulation better?

Insulation does the same thing for a house. The thicker the insulation, the better it works to reduce heat flow from the inside of a home to the outside during winter, and from outside to inside during summer.

Conclusion

Determining the appropriate thickness for blown-in insulation is essential for effective thermal resistance and energy efficiency in buildings. Considerations such as climate, desired R-value, insulation material type, and proper installation techniques are crucial in achieving optimal insulation thickness. Ensuring the right thickness not only provides thermal comfort but also leads to significant cost savings by improving energy efficiency.